Integrated Nanosystems Research Facility

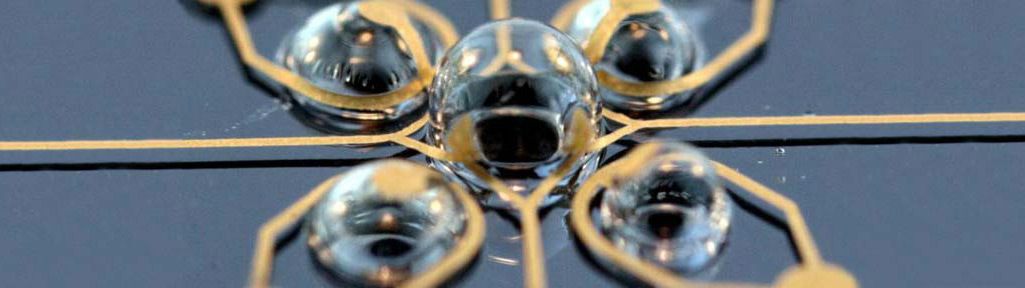

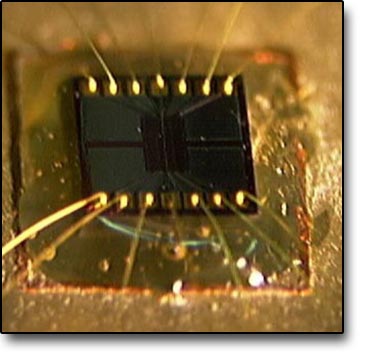

Binary Gas Mass Flow Sensor

Demonstration of device to measure mass flow in natural gas engines. The piece is micromachined silicon, silicon nitride, and gold. Using a 10 micron heater and various temperature sensors, the unit can simultaneously monitor gas flow, direction, and relative concentration of two gases.

Demonstration of device to measure mass flow in natural gas engines. The piece is micromachined silicon, silicon nitride, and gold. Using a 10 micron heater and various temperature sensors, the unit can simultaneously monitor gas flow, direction, and relative concentration of two gases.

Equipment used:

- Laurell Spinner to spin photoresist on silicon wafer.

- Hotplate to soft-bake photoresist.

- KS MA6 Mask Aligner to UV expose and transfer pattern to silicon wafer.

- E-beam 1 Evaporator to deposit platinum heater and temperature sensors.

- E-beam 1 Evaporator to deposit gold electrodes.

- STS silicon etcher to back etch silicon.

- Optical microscope to inspect fabricated chip.

- K&S wire bonder to package fabricated mass flow sensors.