Integrated Nanosystems Research Facility

Research Developments

Here are just a few examples of INRF’s enabling technologies that have been developed since INRF’s inception.

- Demonstration of microfluidic channels system built using UCI technology (shown attached to human forearm). The system is capable of metering nano- and picoliters of fluid and is fabricated in a flexible polymer membrane built from Mylar and Teflon films. An example application could be to monitor blood, or deliver drugs through a patch. Channels remain intact and deliver fluids properly despite considerable handling abuse.

- PMMA PDMS pump device – A hot embossed PMMA pumping device created by Abe Lee’s research group. Utilized theJenOptik in the BiON for hot embossing to develop the device.

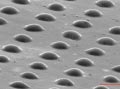

- Lateral Cavity Acoustic Transducer (LCAT), a novel on-chip microfluidic switch that utilizes the acoustic microstreaming generated by an oscillating air-liquid interface to switch cells/particles into bifurcating microchannels. The mold for this device was made via photolithography in INRF by Abe Lee’s research group.

- Elliot Perastaltic. Pumping with on-chip control logic made by Elliot Hui using etched glass and PDMS membrane. Glass is etched in the INRF.

- Khine COC lenses. Microlens array using a combination of shrinkable plastic processing and photolithography. Photolithography done in INRF (Michelle Khine’s device).

- Micropallet Arrays designed to characterize cell populations in tumors. The device actually measures about 1 inch by ½ inch, but it contains 40,0000 – 50,000 individual plastic blocks just large enough for single cells obtained from a biopsy to land on and stick to. This team developed a methodology to connect each antibody to a specific colored nanocrystal, allowing easier identification of the tumor cells after the antibodies attach. (Ed Nelson, G.P. Li and Mark Bachman)

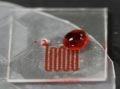

- Zuzanna Siwy and Kenneth Shea have shown that a single hydrophobic nanopore in a PET membrane can undergo reversible wetting and dewetting under the influence of an applied electric field, as predicted by molecular dynamics simulations. The nanopores are made hydrophobic by treating them with (trimethylsilyl)diazomethane. This is a photograph of a water droplet (which measures approximately 2 mm across) on a PET surface that has been treated in this way to make it hydrophobic.