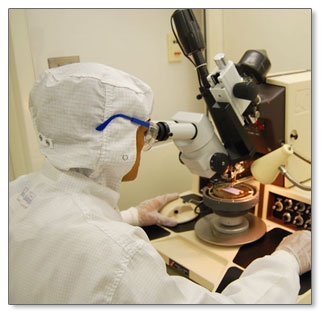

Integrated Nanosystems Research Facility

K&S Gold Ball Bonder

The K&S Gold Ball Bonder is a thermosonic unit. The bonding is done at a lower temperature with additional ultrasonic energy. The 4124 operates in two modes, a semiautomatic and manual movement of the bonding head. The unit has a 1-mil gold wire installed and is capable of a 152mm x 152mm bonding area.

Process Description

Once a die chip has been attached to a package, wire bonding is one method of making the connection between the die and the package. Gold as a bonding wire is a room-temperature conductor, a heat conductor and resistant to oxidation and corrosion. Gold wire bonding has two basic methods: thermocompression and thermosonic. Basically, the gold wire is fed through a capillary; an electrical spark melts the tip to form a ball; and then the capillary moves downward to touch the bonding pad. After pressure, the capillary moves upward release some wire and then positioned to make the second bond.