Integrated Nanosystems Research Facility

Newsletter Issue 9

June 28| Issue 9

Welcome to the new INRF monthly newsletter where we will be sharing equipment capabilities, updates and research accomplishments.

INRF Spotlight – Metal Mold Foundry Service

The INRF has been offering foundry services for the fabrication of microfluidic devices using various processes.

The STS System silicon deep reactive ion etching (DRIE) is used to fabricate micro-channels directly onto a silicon wafer and is also used to make silicon mold for PDMS casting of the microfluidic device. The other mold making method is to use SU-8 photoresist epoxy.

The SPTS APS glass etcher is used to dry etch micro-channels directly onto glass substrates (including Pyrex and fused silica).

Now INRF is pleased to announce the addition of metal mold making for microfluidics and biochips fabrication to its foundry services. The new process will complement the existing fabrication methods, by imprinting the metal mold onto PMMA using the nano-imprinter. The metal molds can also be used for PDMS or any other polymer casting.

The metal mold making process can now achieve over 50 microns in height and taller structures will be developed in the near future.

INRF will be showcasing fabricated microfluidics and biochips devices based on these metal molds in our future newsletters.

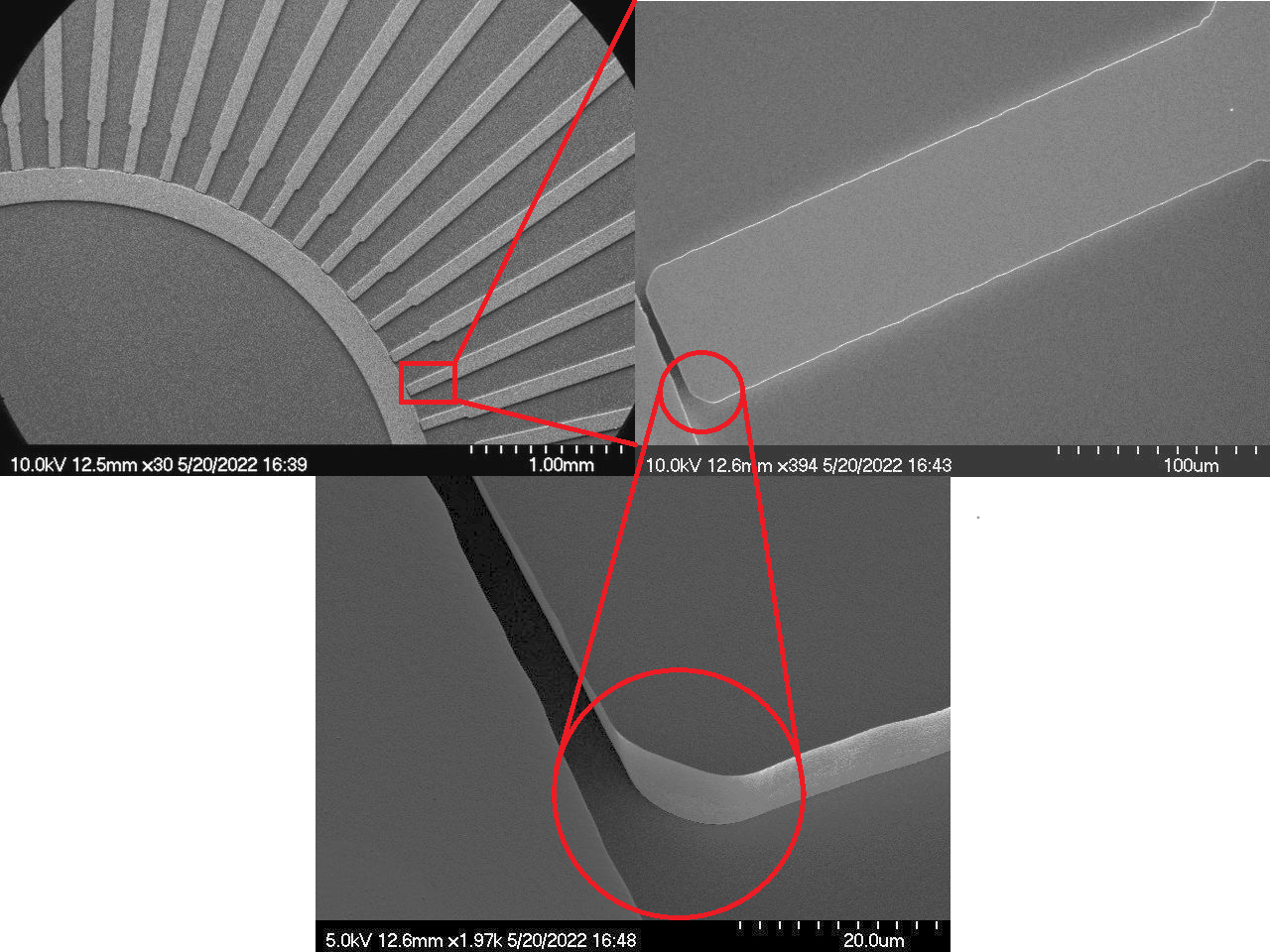

Below are some SEM images that highlight the metal mold structures. The scanning electron microscope images represent an example of a biochip metal mold with the following dimensions of 100 microns, 150 microns in width and 25 microns in height.