Integrated Nanosystems Research Facility

Newsletter Issue 7

November 19 | Issue 7

Welcome to the new INRF monthly newsletter where we will be sharing equipment capabilities, updates and research accomplishments.

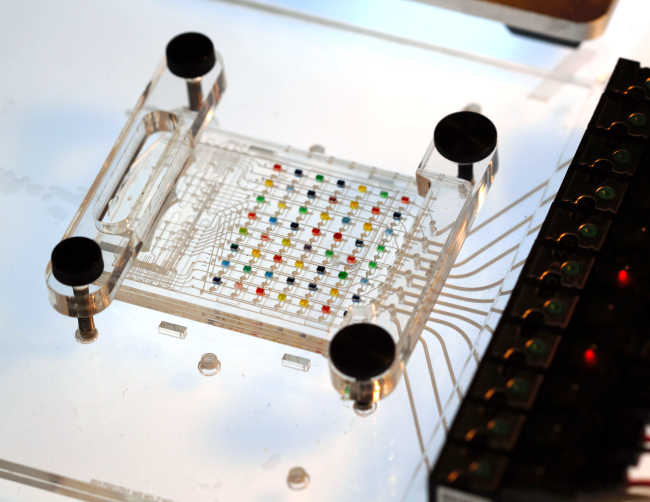

Faculty Spotlight – Elliot Hui

We present this month a member of the INRF research community, Elliot Hui. As an electrical engineering graduate student at Berkeley, Elliot spent long hours in the cleanroom building 3D thin-film silicon MEMS structures. As a bioengineering postdoc at MIT, he then shifted to tissue engineering, continuing to make use of microfabrication but now for patterning liver cells. Since joining UC Irvine Biomedical Engineering in 2008, Elliot’s research has drawn from both fields that he trained in. For example, his group has built computers out of microfluidic circuits, essentially miniaturized plumbing that can think, and they are now leveraging this technology to build platforms for testing immense numbers of drugs and drug combinations in nanoliter volumes. Their cell micropatterning technologies have most recently been employed for studying the morphogen gradients that control pattern formation in early embryonic development. In addition, they have developed a new type of thermal microvalve that enables a complex set of liquid handling operations to be automated in a simple, passive device. For example, this may allow screening of Covid-19 mutational variants for the same cost and labor as currently required for a single Covid test. Their research group continues to make heavy use of microfabrication while also employing rapid prototyping technologies such as laser cutting and 3D printing.

Richard Chang, Senior Process Engineer

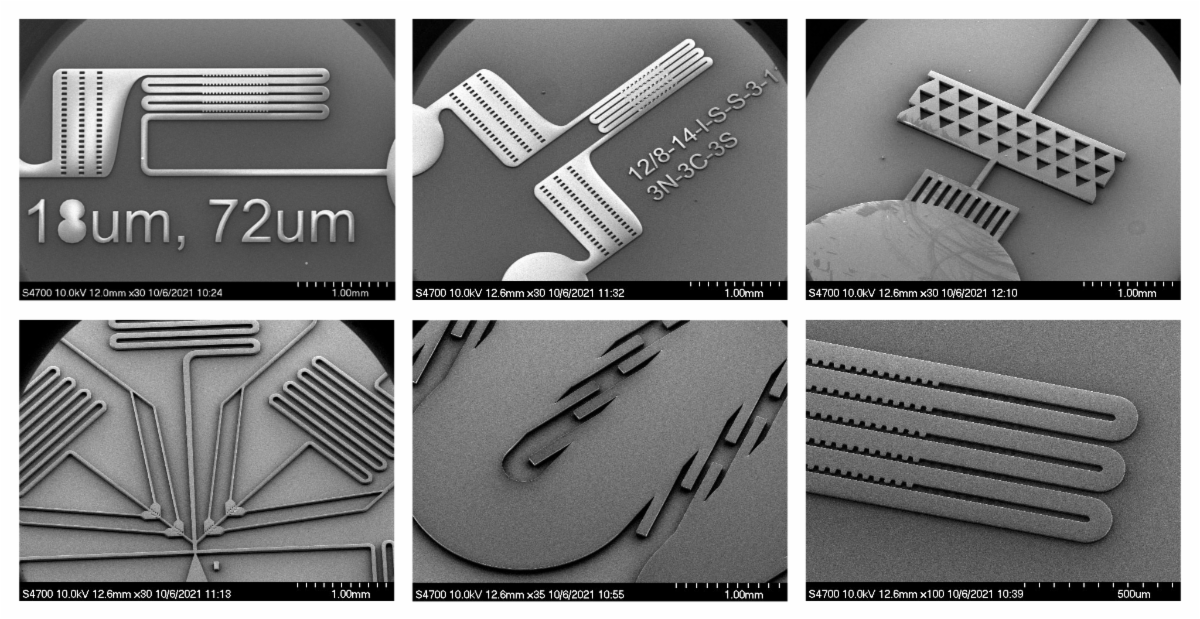

The BiON cleanroom offers the ability to fabricate Lab-on-a-chip (LOC) devices based on microfluidic and MEMS process fabrication technologies. These devices have applications in biological, biomedical and other related fields.

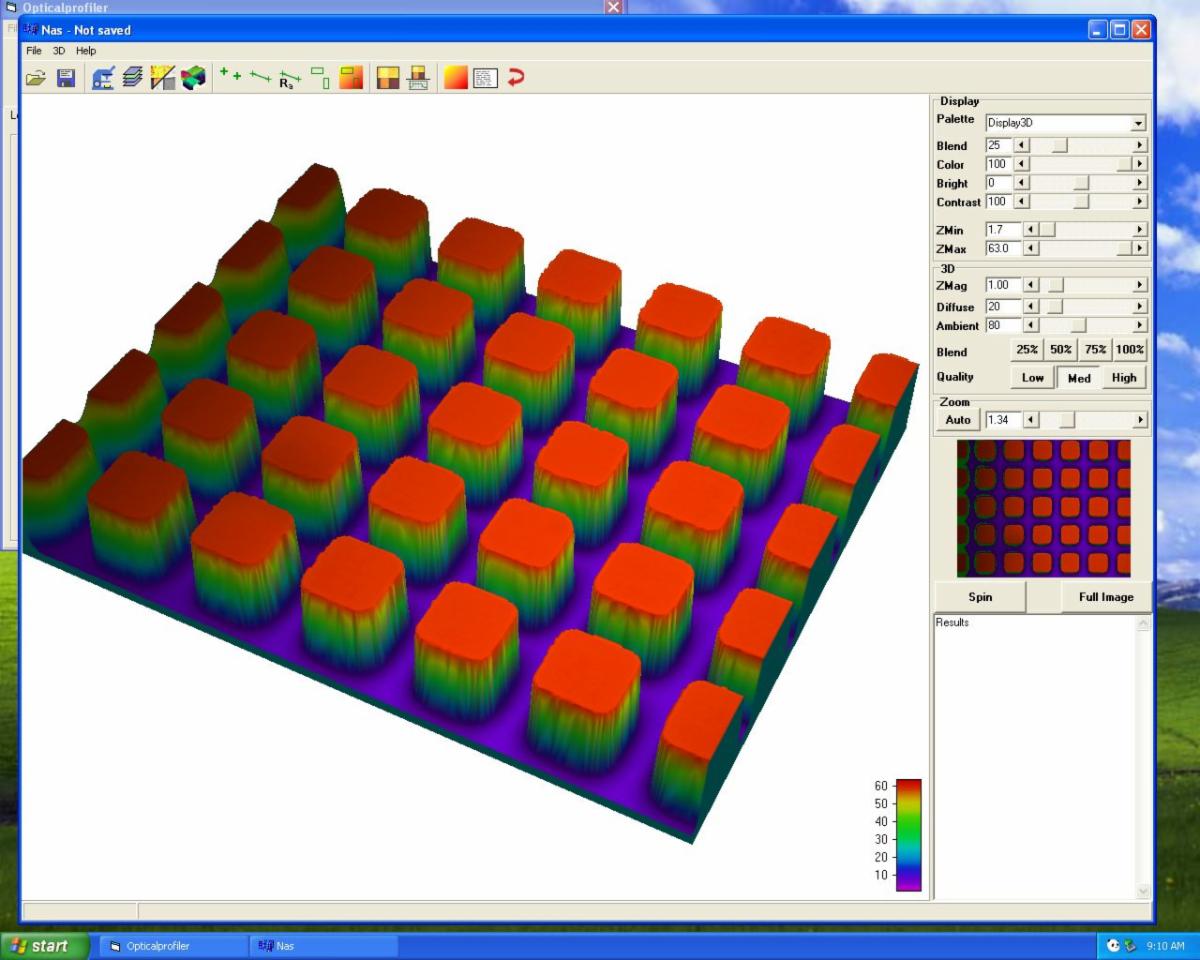

The BiON has the necessary tools to fabricate and test microfluidic chips with channel feature size from microns to millimeters. Depending on the application, the devices can be fabricated on different substrates such as silicon, glass, ceramics, metals and polymeric materials. Various methods can be used during fabrication process. The Laser Ablation System allows etching micro channels on various substrate. The SPTS System creates features and micro channels with vertical walls on glass and ceramics substrates. The Nano-imprinter allows hot embossing of polymeric material substrates with feature size down to the nanometer. The SU-8 mold fabrication allows casting of PDMS microfluidic devices.

Below are photos of various devices fabricated in the BiON cleanroom.