Integrated Nanosystems Research Facility

Newsletter Issue 2

April 1 | Issue 2

Welcome to the new INRF monthly newsletter where we will be sharing equipment capabilities, updates and research accomplishments.

Faculty Spotlight – Hung Cao

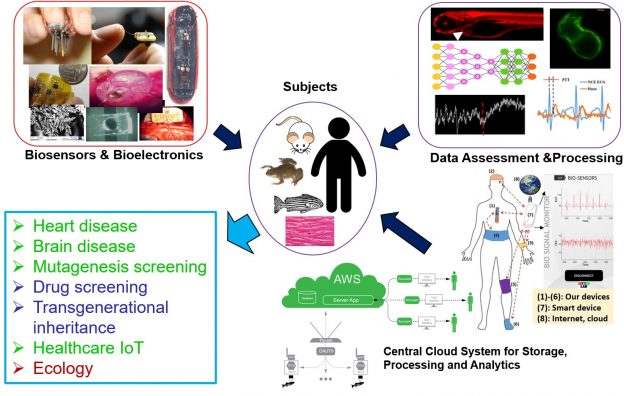

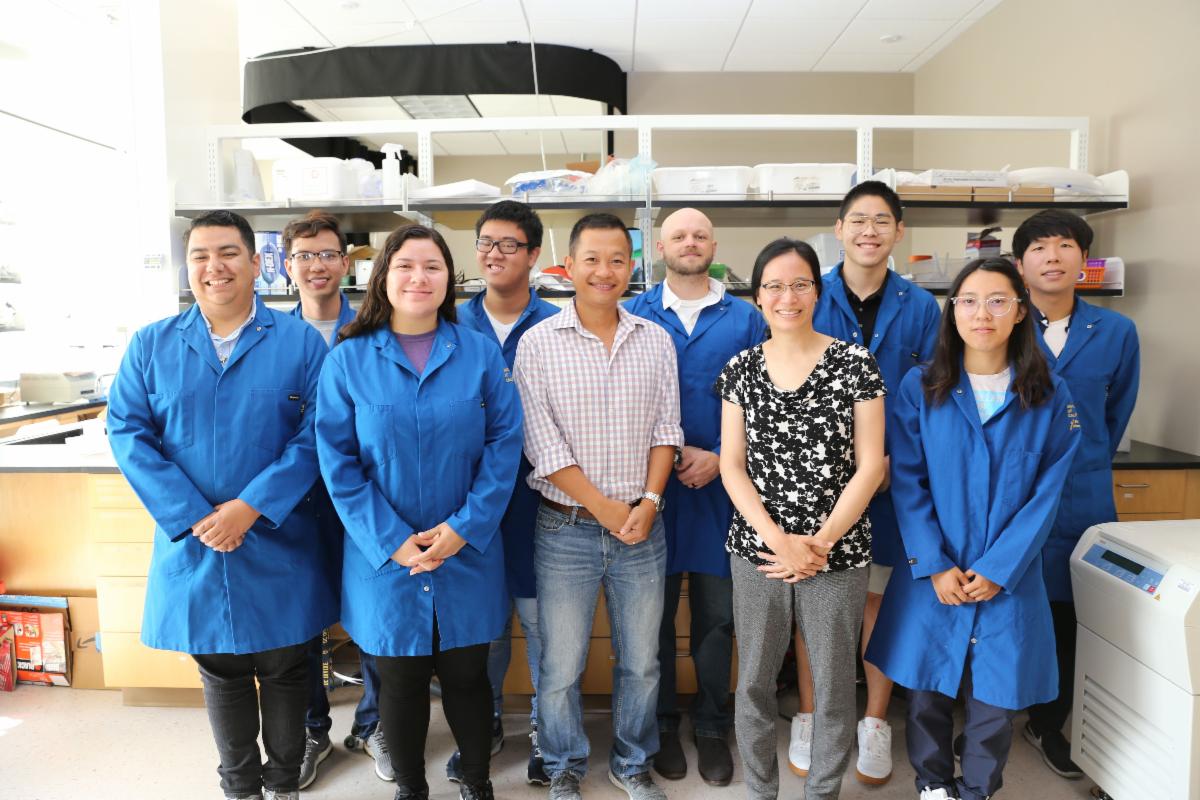

This month we spotlight a member of the INRF research community, Hung Cao. Hung Cao received his B.Sc. degree in electronics and telecommunications from Hanoi University of Science and Technology, Vietnam in 2003. He then served as a lecturer at Vietnam Maritime University from 2003 to 2005. He earned an M.Sc. and Ph.D. in electrical engineering from the University of Texas at Arlington in 2007 and 2012, respectively. After his Ph.D. study on biosensors and bioelectronics, Cao received training in bioengineering and medicine at University of Southern California (2012-2013) and University of California, Los Angeles (2013-2014). In 2014-2015, he worked for ETS, Montreal, QC, Canada as a research faculty. In fall 2015, Cao became an assistant professor of electrical/biomedical engineering at University of Washington (UW). Cao joined the UC Irvine Department of Electrical Engineering and Computer Science in September 2018. His HERO lab focuses on the applications of micro- bio-sensors and bioelectronics for health monitoring in humans as well as biological studies in animal models. Cao is one of the pioneers in utilizing flexible microelectronics to study heart disease in zebrafish. He is a recipient of the UW’s RRF Award (2016), the NSF CAREER Award (2017) and one of the only two nominees under UW competing for the prestigious Moore’s Inventor Fellowship (2017).

We develop novel tools to explore biology and improve healthcare. Micro- and nano-technologies together with sensing and wireless innovations have been emerging recently as essential assets to enhance healthcare and life-science investigations. Cost and care efficiency, quality and efficacy in hospitals, as well as pharmacology and science discoveries have obtained great benefits from multidisciplinary researches. While micro- and nano-fabrication provided miniaturized sensors and systems with better sensitivity, selectivity and longevity at minimal power consumption; wireless technology and innovations in electronics helped in cutting healthcare cost, bringing convenience to patients and establishing distanced care which was recently defined as personalized- and tele-medicine of the mobile-health (m-Health) network. Towards this end, the objectives of HERO laboratory are to introduce a paradigm shift of applying innovative engineering tools for biological investigations and to bridge expertise in different fields providing novel healthcare devices.

Here are our current projects

- Acquisition and analysis of electrocardiogram in zebrafish for cardiac disease studies and drug screening

- Development of wireless pH sensing systems for biological and environmental monitoring

- Acquisition and extraction of fetal ECG and maternal ECG via an unobtrusive patch and a cloud system

- Non-contact electrode-based devices for electrophysiological monitoring

- Micro/nanofluidic devices for isolation and assessment of mitochondria

- EEG acquisition and analysis in rodents and humans for studies of neurological diseases, focusing on traumatic brain injury and epilepsi

- Dual L-glutamate/GABA microprobes to study the role of early life sleep disruption toward autism using the prairie vole model

- Acquisition and analysis of electrophysiology in Xenopus

This month we are highlighting our

Resonetics Laser Ablation System

System Model: Resonetics Rapid X25

Laser Source: COMPexPro 110 Excimer Laser

Pattern Design Software: CADFusion

Motion Control Software: Aerotech A3200

| Chuangyuan “CY” Lee, Senior Process Engineer |

| The Resonetics Rapid X250 Laser System uses a Coherent COMPexPro® 110 excimer laser to generate short, high intensity pulses of ultraviolet (UV) light. The tool has a wide variety of applications, including micromachining, surface cleaning, marking, and medical applications. If you have any questions or interest in using this equipment please contact CY at the INRF. |

Tool Specifications:

- Light wavelength: ArF 193 nm and KrF 248 nm

- Motorized stage in 4 axis: X, Y, Z, Rotation (R)

- X/Y stage travel range: 200 x 200 mm

- Maximum laser repetition rate: 100 Hz

- Maximum laser pulse energy: 120 mJ

- Laser pulse duration: 20 ns

- Minimum feature size: 10 µm

- Ablation speed: 0.01~2.4 mm/s (depending on laser spot size and repetition rate)

Tool Specifications:

- Porous ceramic vacuum chuck for wafer up to 6”

- Class 1 laser system with interlock features

- Safety Fluorine and exhaust sensors in place

- Able to ablate various materials, including silicon, glass, polymers, and metals

- Optical microscope and Dektak profilometer on site for easy inspection and characterization

- CADFusion software (to generate G code) and Aerotech A3200 motion controller on the PC. Capable of dxf file (e.g., from AutoCAD) import.

Sample Results

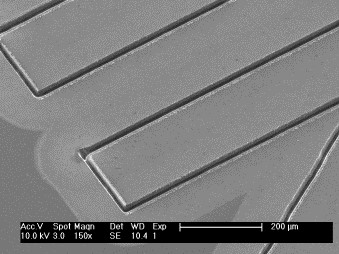

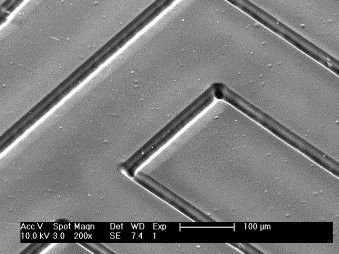

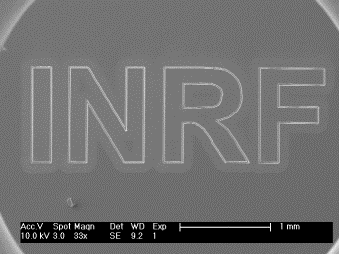

Optical and SEM images of “INRF” pattern. It was designed on AutoCAD, imported to CADFusion, and ablated on glass substrate.

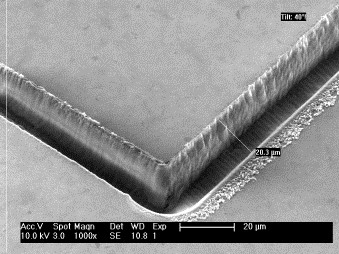

SEM of microchannels fabricated on glass substrate. 20um lines in design were lasered to be around 20.3um wide.

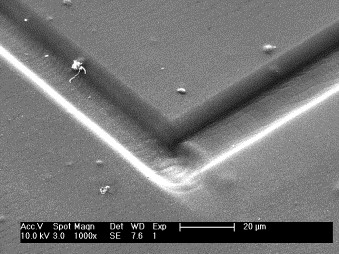

SEM of ablated Kapton polyimide. The sidewall edge is smooth and well-defined.